Explore a world of applications with METHONOVA™

Methyl cellulose assays

A polymer of choice in semi-solid matrices for the purpose of colony forming cell assays (CFC) is methyl cellulose.

METHONOVA™ is our cutting-edge methyl cellulose, tested for cell compatibility and suitable for cell assays. Typically, a 1-1.5% concentration of methyl cellulose is employed in these assays. Thanks to its high viscosity, methyl cellulose facilitates cell proliferation and aggregation, benefiting cell counting and colony selection.

Discover how METHONOVA™ can elevate your cell assays with precision and performance.

Cell culture media

The biopharmaceutical market continues to grow at a rapid pace, fueling the need for cells to produce proteins, cell or gene therapies. However, cell production stands as a major bottleneck within the industry, impacting both production timelines and the cost-effectiveness of biopharmaceutical therapies.

To improve production yields, cell culture media have been significantly optimized over the last few years. Additionally, the industry is evolving away from animal-based solutions, towards the adoption of xeno-free products. METHONOVA™ is a sustainably sourced methyl cellulose that is suitable for use in cell culture media.

Suspension cells

Certain cells can be grown in suspension, such as the commonly used Chinese Hamster Ovary (CHO) cells, which are used for the production of monoclonal antibody (mAb) drugs. To enhance production yields of suspension cells, extensive efforts have been devoted to reducing stress factors and optimizing upstream processes.

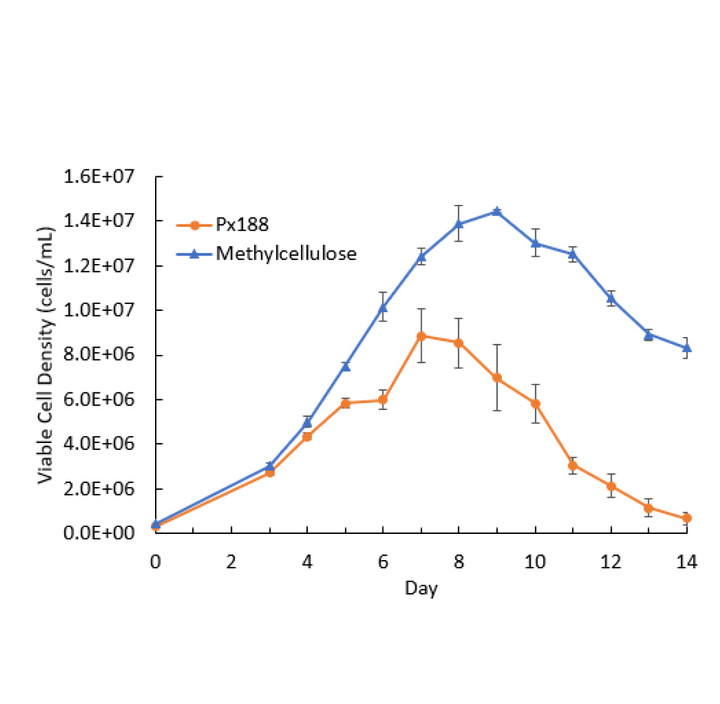

One innovative approach involves the strategic use of additives to boost cell production. Take, for instance, Poloxamer 188 (Px188), an additive that acts as a shear protectant. It has now become a staple in many commercial media products. Notably, methyl cellulose can also be used as a media additive for elevating viable cell density in CHO cell cultures. (see Figure 1).

Unlock the potential of METHONOVA™ as an additive to improve your cell culture processes and elevate production efficiency. Figure 1. Viable DG-44 CHO cell density in shake flask suspension with Methyl Cellulose vs. Poloxamer 188

Adherent cells

Adherent cells, such as mesenchymal and induced pluripotent (MSC & iPSC) stem cells, typically bind to surfaces, such as T flasks, microcarriers or other suitable 3-Dimensional (3D) environments to aid expansion. After the cells have proliferated, they are usually removed from the surfaces using the enzyme trypsin to cleave the cell’s binding proteins. However, this process can damage the cells, potentially impacting production yields and introducing inconsistent therapeutic potency.

The ability to form cell aggregates, also known as spheroids, is gaining interest as an alternative 3D model for cell growth, particularly for stem cell producer cells. Similar to its application in cell assays, methyl cellulose can protect these cells from adhering to surfaces, supporting optimal colony formation.

Cryopreservation

Cryopreservation is a necessary step to preserve nearly all cells and cellular therapies, and is particularly important for immunogenic therapies, such as chimeric antigen receptor (CAR)-T cells. Successful cryopreservation depends on many factors including the process itself – like freeze and thaw time or temperature – as well as the use of cryoprotectants. As the industry moves away from animal-derived serum and traditional cryoprotection agents like dimethyl sulfoxide (DMSO), Methyl Cellulose has become a popular alternative.

3D bioprinting

One of the newer frontiers in biopharma is the transition from 2D to 3D cell growth, mimicking an in-vivo like environment to promote nutrient distribution and eventually cell proliferation. With the push to eliminate the use of animal derived products such as extracellular matrices, non-animal derived hydrogels are increasingly investigated for the formation of scaffolds for directed cell growth.

Hydrogels containing methyl cellulose, in addition to other biopolymers such as hyaluronic acid or alginates, can be used for molding applications such as 3D bioprinting. The thermo-responsive behavior of methyl cellulose allows for gel formation and cell growth – and by reducing the temperature the methyl cellulose can be removed. Using methyl cellulose for this application is particularly useful for creating softer gels.

Do you have questions regarding METHONOVA™ applications or are you interested in buying the product? Get in touch!

Do you have questions regarding METHONOVA™ applications or are you interested in buying the product? Get in touch!